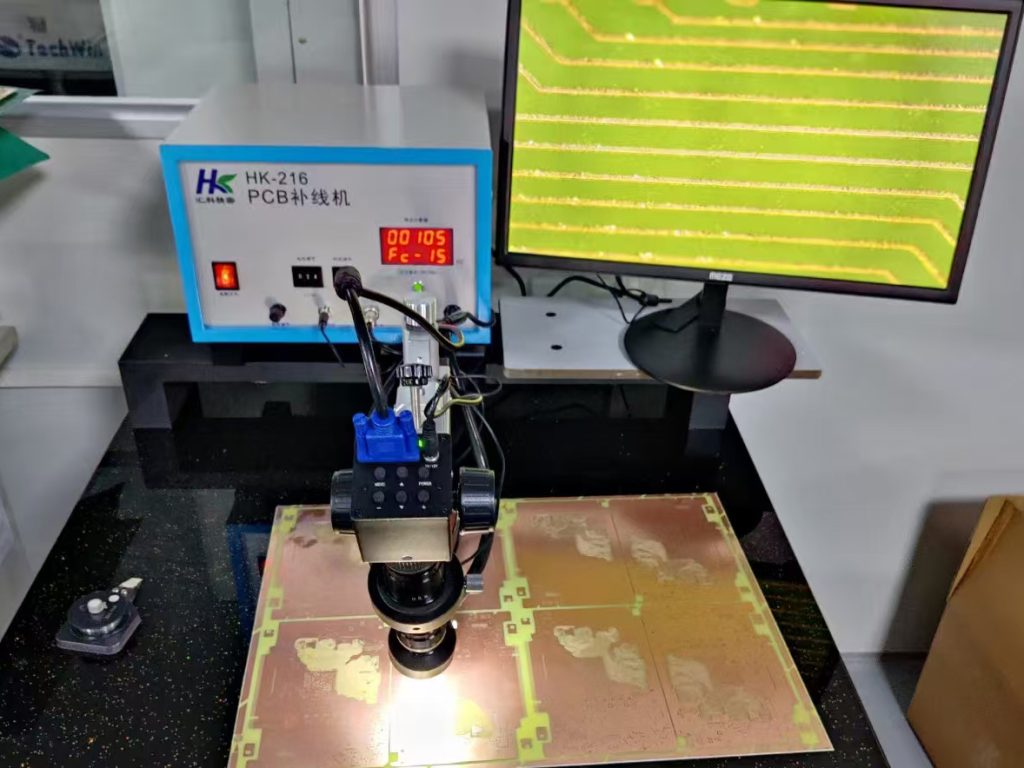

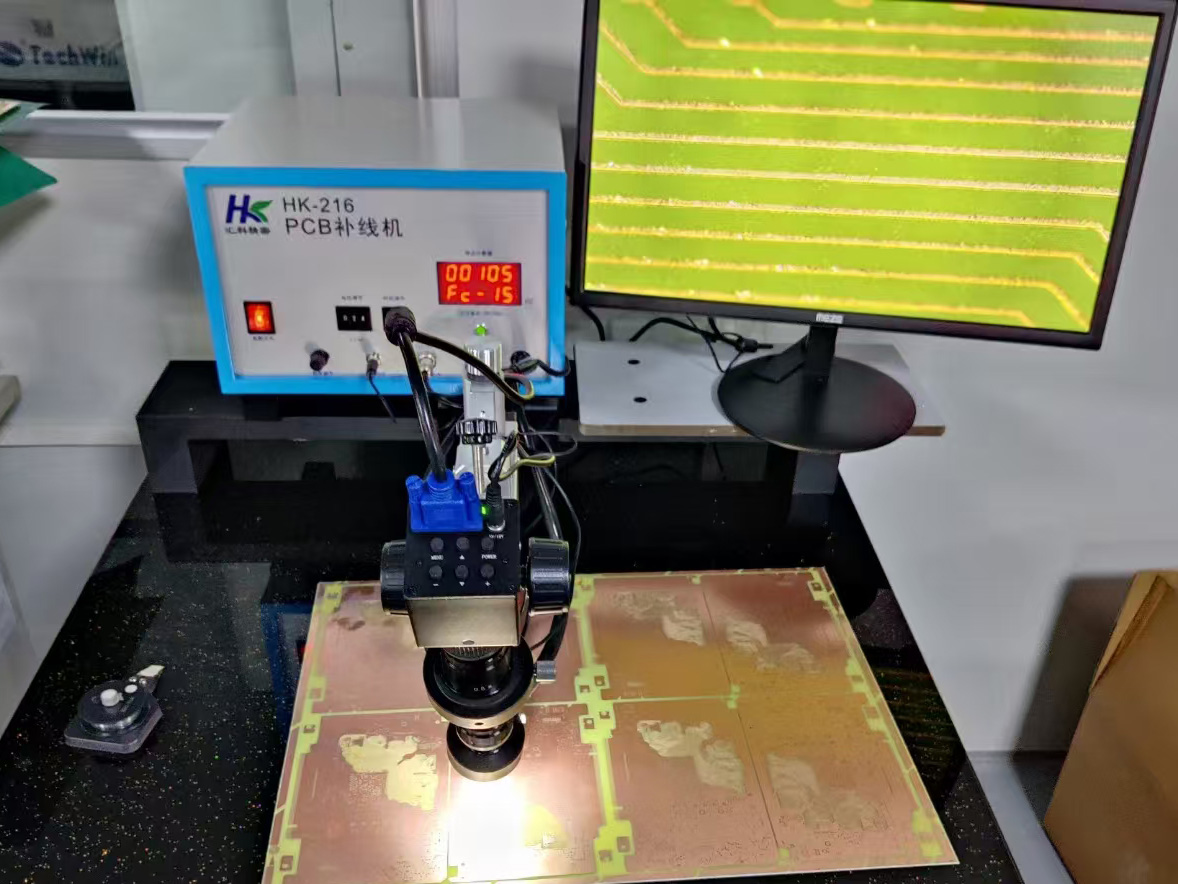

In the field of electronic manufacturing, the patching machine is the key equipment for repairing PCB board defects, and the microscope camera is the “eye” of the patching machine, providing visual guarantee for precision repair. With the development of electronic products towards miniaturization, the patching process has higher and higher requirements for precision, and the application of microscope cameras has become particularly important.

–Working principle and core functions of the patching machine

The patching machine is mainly used to repair line defects such as open circuits and short circuits on PCB boards. Its working principle is to locate the defect position through a high-precision motion system, remove the defect by laser or mechanical means, and then re-establish the connection by copper plating or welding. The entire repair process requires micron-level accuracy, which places extremely high demands on the visual system.

The core functions of the patching machine include defect positioning, path planning, and repair execution. Among them, the accuracy of defect positioning directly affects the repair effect, and the microscope camera is the key component to achieve precise positioning. The positioning accuracy of modern patching machines can reach ±1μm, which is mainly due to the application of high-performance microscope cameras.

In PCB board repair, microscope cameras play an irreplaceable role. It not only needs to identify micron-level defects that are difficult to observe with the naked eye, but also provides real-time monitoring for the repair process to ensure the quality of repair.

—Specific application of microscope camera in wire repair machine

In the defect detection link, the microscope camera captures the surface image of the PCB board through a high-magnification optical system, and cooperates with the image processing algorithm to accurately identify line defects. The resolution of modern microscope cameras can reach 0.5μm/pixel, which can clearly display line defects with a line width of 20μm.

In line positioning, the microscope camera uses multi-field stitching technology to achieve high-precision positioning over a large range. In conjunction with the motion system of the wire repair machine, the positioning accuracy can reach ±1μm, meeting the requirements of precision repair. Some high-end wire repair machines are also equipped with 3D imaging functions to accurately measure line height information.

In the monitoring of the repair process, the microscope camera collects images of the repair area in real time and monitors the repair quality through image analysis algorithms. This real-time monitoring function greatly improves the success rate of repair and reduces the failure rate of repair to below 0.1%.

–Technical advantages and future development of microscope cameras

Microscope cameras show significant technical advantages in wire repair machines. High-resolution imaging capability can clearly display micron-level circuit structures, fast image acquisition capability meets real-time monitoring needs, and stable optical performance ensures long-term working reliability. These advantages make it an indispensable component of the wire repair machine.

Microscope cameras play a key role in improving the performance of wire repair machines. High-precision imaging improves the accuracy of defect recognition, fast image processing speeds up repair, and intelligent algorithms optimize the repair path. These improvements have increased the repair efficiency of wire repair machines by more than 30%.

As the “eyes” of wire repair machines, microscope cameras play an irreplaceable role in precision repair. With the advancement of technology, microscope cameras will continue to promote the improvement of wire repair machine performance and provide strong support for the development of the electronics manufacturing industry. In the future, the combination of more advanced imaging technology and intelligent algorithms will enable the line filling process to reach new heights and meet the needs of the miniaturization of electronic products.

It is a pity, that I can not participate in discussion now. It is not enough information. But this theme me very much interests.

Thank you for your support.You can disscuss with us on WhatsApp +8613246797702

It was specially registered at a forum to tell to you thanks for the help in this question how I can thank you?

Thank you for your support.You can disscuss with us on WhatsApp +8613246797702