Machine vision is often used to replace artificial vision in dangerous working environments suitable for manual operations or occasions where artificial vision cannot meet the requirements. At the same time, in large-scale industrial production processes, the efficiency and accuracy of product quality inspection using artificial vision are low, and the use of machine vision inspection methods can greatly improve production efficiency and the degree of automation of production. Moreover, machine vision is easy to realize information integration and is the basic technology for realizing computer integrated manufacturing.

It is precisely because machine vision systems can quickly obtain a large amount of information, and are easy to process automatically, and are easy to integrate with design information and processing control information. Therefore, in modern automated production processes, people use machine vision systems widely in the fields of working condition monitoring, finished product inspection and quality control.

To learn more about machine vision information, you can visit China’s first machine vision media China Vision Network, which was established in June 2003.

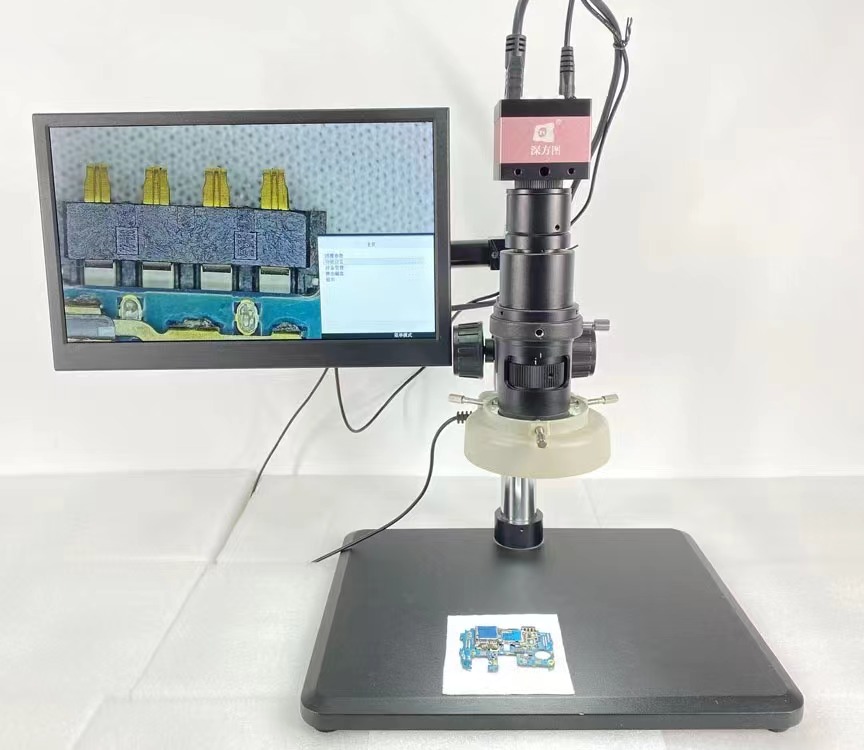

A typical industrial machine vision system includes: light source, lens, camera (including CCD camera and COMS camera), image processing unit (or image capture card), image processing software, monitor, communication/input and output unit, etc.

Working Principle

The machine vision inspection system uses a CCD camera to convert the inspected target into an image signal, which is then transmitted to a dedicated image processing system. Based on the pixel distribution, brightness, color and other information, it is converted into a digital signal.

The image processing system performs various operations on these signals to extract the characteristics of the target, such as area, quantity, position, and length, and then outputs the results based on the preset tolerance and other conditions, including size, angle, number, qualified/unqualified, presence/absence, etc., to achieve automatic recognition.